Table of Contents

Managing a fleet of vehicles is no longer just about keeping track of where your trucks are. In 2026, artificial intelligence has transformed the fleet management system into a strategic business asset that directly impacts your bottom line, operational efficiency, and competitive advantage.

This guide breaks down everything you need to know about AI-powered fleet management in a clear, actionable format designed for business decision-makers.

What is Fleet Management?

The Business Definition

Fleet management is the strategic oversight of all commercial vehicles within your organization from purchase to disposal. A modern fleet management system is a digital platform that automates, optimizes, and streamlines every aspect of this process.

What It Actually Does For Your Business

Understanding the transformation from traditional to AI-powered fleet management helps illustrate the dramatic operational improvements possible with modern technology.

Before AI-Powered Systems:

- Manual vehicle tracking and paperwork – Fleet managers spent hours updating spreadsheets and filing documents, with data often outdated by the time it was recorded

- Reactive maintenance (fix it when it breaks) – Vehicles failed unexpectedly, causing costly downtime and emergency repairs at premium rates

- Guesswork on route planning – Dispatchers relied on experience and intuition, missing optimization opportunities that technology can identify

- High fuel costs and inefficiencies – Without data-driven insights, fuel waste from poor routes and driver behaviors went undetected

- Limited driver performance visibility – Managers only learned about problems after accidents or customer complaints occurred

With AI-Powered Fleet Management Systems:

- Real-time automated tracking and analytics – Every vehicle’s status updates continuously, with AI analyzing patterns and generating actionable insights automatically

- Predictive maintenance (fix it before it breaks) – The system identifies potential failures weeks in advance, allowing scheduled repairs during convenient times

- AI-optimized routing that saves time and fuel – Algorithms process millions of variables to create the most efficient routes, adjusting dynamically as conditions change

- 15-25% reduction in fuel costs – Intelligent routing combined with driver behavior monitoring eliminates unnecessary fuel consumption

- Complete driver behavior insights with coaching – Detailed performance metrics enable targeted coaching that improves safety and efficiency

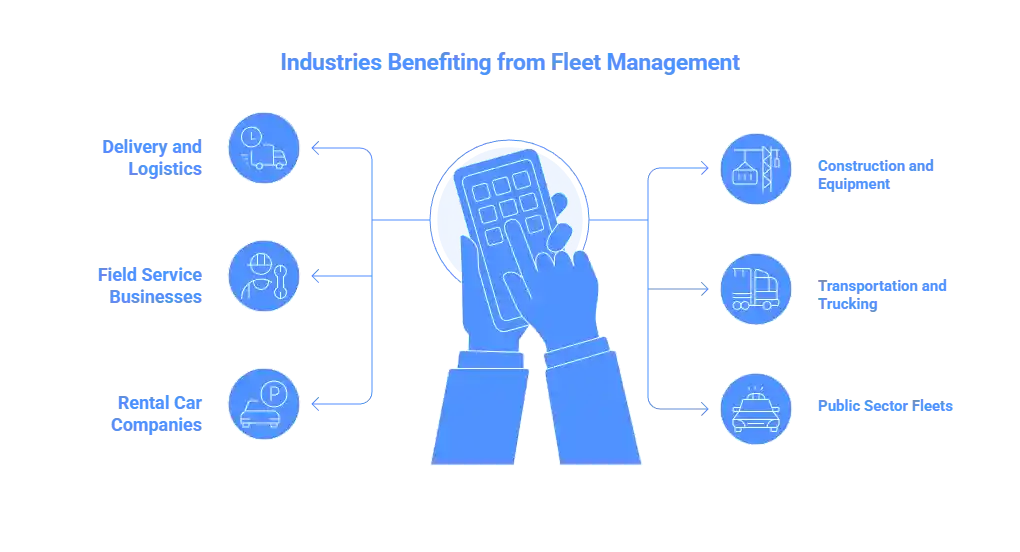

Who Needs This?

A fleet management system delivers measurable value across diverse industries where vehicles represent significant capital investment and operational expense.

- ✓ Delivery and logistics companies – Where every minute and mile directly impacts profitability and customer satisfaction

- ✓ Construction and equipment fleets – Where equipment downtime can halt entire projects and cost thousands per hour

- ✓ Field service businesses – Where technician productivity depends on efficient routing and vehicle reliability

- ✓ Transportation and trucking operations – Where compliance, safety, and fuel costs are critical success factors

- ✓ Rental car companies – Where vehicle utilization, maintenance timing, and fleet turnover drive margins

- ✓ Public sector vehicle fleets – Where taxpayer accountability and budget constraints demand maximum efficiency

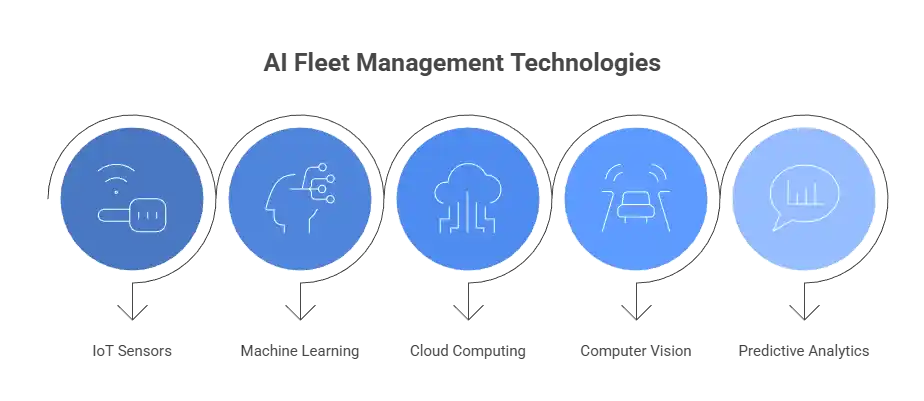

Technologies Behind AI-Enabled Fleet Management

The Tech Stack (Simplified)

A modern fleet management system combines several technologies working together seamlessly. Understanding these components helps you evaluate vendor capabilities and make informed purchasing decisions.

1. IoT Sensors & Telematics → The Data Collectors

These hardware devices installed in your vehicles serve as the sensory system, constantly gathering operational data.

- GPS tracking devices – Provide location updates every 30-60 seconds with accuracy within 3-5 meters for precise routing and geofencing

- Engine diagnostics sensors – Monitor 50+ vehicle parameters, including RPM, temperature, and error codes, for comprehensive health tracking

- Fuel monitoring systems – Track consumption in real-time and detect anomalies that indicate theft, fraud, or mechanical issues

- Temperature and cargo sensors – Essential for refrigerated transport and sensitive goods requiring documented environmental conditions

- Business Impact: Real-time visibility into every vehicle’s location, condition, and performance, eliminating the blind spots that plague traditional fleet management

2. Machine Learning → The Brain

Machine learning algorithms transform raw data into actionable intelligence, continuously improving their accuracy as they process more information.

- Analyzes patterns from millions of data points – Identifies correlations between weather, traffic, driver behavior, and outcomes that humans cannot detect

- Learns from past performance – Understands which routes consistently run late, which vehicles require more maintenance, and which drivers excel

- Makes intelligent predictions – Forecasts maintenance needs, traffic delays, and optimal resource allocation with 85-95% accuracy

- Improves accuracy over time – Self-optimizing algorithms become more precise as your fleet generates more operational history

- Business Impact: Automated decision-making that gets smarter daily, reducing reliance on human guesswork and institutional knowledge

3. Cloud Computing → The Processing Power

Cloud infrastructure provides the scalable computing resources necessary to process massive data volumes from distributed fleets.

- Handles data from thousands of vehicles simultaneously – Processes millions of data points per hour without performance degradation

- Accessible from anywhere, anytime – Managers monitor operations from office, home, or mobile devices with identical functionality

- Automatic updates and scaling – New features deploy seamlessly, and system capacity expands automatically as your fleet grows

- Business Impact: No expensive IT infrastructure needed, avoid capital expenditure on servers, eliminate maintenance overhead, and ensure 99.9%+ uptime

4. Computer Vision → The Eyes

AI-powered visual analysis transforms cameras from simple recording devices into intelligent safety and coaching tools.

- Dashboard cameras with AI analysis – Continuously evaluate driver attention, phone usage, and dangerous behaviors in real-time

- Detects unsafe driving behaviors – Identifies distraction, drowsiness, and aggressive maneuvers the moment they occur, not after accidents

- Monitors road conditions – Recognizes hazards like ice, pedestrians, and obstacles, providing warnings to drivers

- Business Impact: Prevents accidents before they happen through immediate intervention and objective coaching based on visual evidence

5. Predictive Analytics → The Fortune Teller

Advanced analytics engines forecast future events with remarkable accuracy, enabling proactive rather than reactive management.

- Forecasts maintenance needs – Predicts component failures 2-4 weeks before they occur based on sensor data patterns and usage

- Predicts traffic and delays – Analyzes historical patterns, current conditions, and external data to forecast congestion and recommend alternatives

- Estimates fuel costs – Projects expenses based on market trends, planned routes, and seasonal factors for accurate budgeting

- Business Impact: Plan instead of reacting to schedule maintenance during downtime, avoid congestion, and optimize fuel purchasing

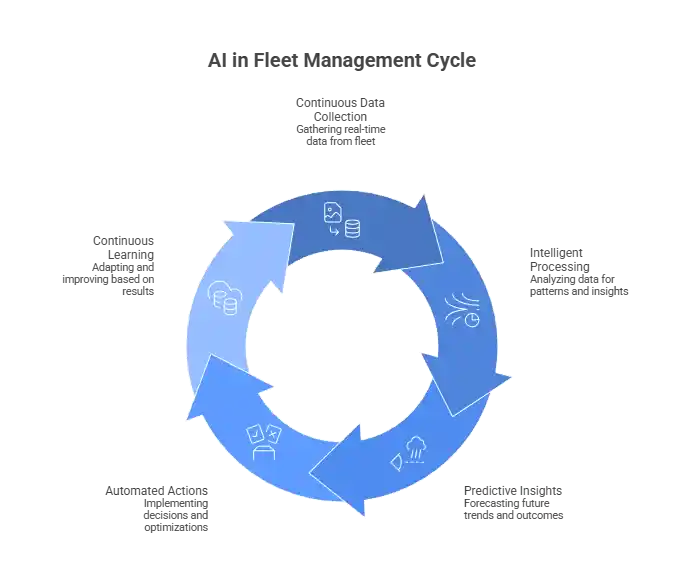

How Does AI in Fleet Management Work?

The 5-Step Process Behind the Scenes

Understanding the technical workflow helps you appreciate how your fleet management system transforms raw data into business value automatically and continuously.

STEP 1: Continuous Data Collection

The foundation of AI-powered fleet management is comprehensive, real-time data gathering from every vehicle in your operation.

Your fleet management system gathers data 24/7:

- Vehicle location every 30-60 seconds – GPS coordinates create a detailed movement history for route analysis and geofence monitoring

- Engine diagnostics in real-time – OBD-II data streams provide continuous updates on engine health, fuel consumption, and error codes

- Driver behavior continuously – Accelerometer and gyroscope sensors track acceleration, braking, cornering, and other driving dynamics

- Fuel consumption per trip – Detailed tracking correlates fuel use with specific routes, loads, and driver behaviors for precise analysis

- Maintenance sensor readings – Oil quality, brake pad thickness, tire pressure, and other wear indicators provide early warning of service needs

Data Volume: A 100-vehicle fleet generates 50+ million data points monthly an impossible amount for manual analysis but ideal for AI processing

STEP 2: Intelligent Processing

Raw data becomes useful intelligence through sophisticated AI algorithms that work continuously in the background.

AI algorithms analyze this data instantly:

- Identifies patterns humans can’t see – Machine learning detects subtle correlations between weather conditions, driver fatigue, vehicle age, and performance outcomes

- Compares against historical benchmarks – Every metric is evaluated against your fleet’s past performance and industry standards to identify anomalies

- Detects anomalies requiring attention – Statistical analysis flags outliers that indicate problems, opportunities, or unusual circumstances warranting investigation

- Correlates multiple factors simultaneously – AI considers hundreds of variables together to understand root causes rather than just symptoms

Speed: Processes in milliseconds what would take humans weeks. The system analyzes your entire fleet’s performance and generates insights while managers handle other priorities

STEP 3: Predictive Insights

The most powerful capability of modern fleet management systems is forecasting future events before they impact operations.

Your fleet management system looks ahead:

- “Vehicle #47’s transmission will likely fail in 2-3 weeks” – Based on temperature patterns, shift behavior, and fluid analysis that indicate impending failure

- “Route A will have heavy traffic delays Tuesday morning” – Using historical traffic data, event schedules, and weather forecasts to predict congestion

- “Driver Smith’s recent behaviors indicate elevated accident risk” – Combining fatigue patterns, recent violations, and behavioral changes that precede incidents. While AI aims to prevent these scenarios, fleet managers must still be prepared to engage a Denver car accident attorney if a serious incident does occur

- “Fuel prices in your region will rise 8% next week” – Analyzing market trends, seasonal patterns, and supply factors to optimize purchasing timing

Accuracy: 85-95% for most predictions with mature systems, precision improves as the AI learns from your specific fleet’s historical patterns and outcomes

STEP 4: Automated Actions

AI-powered systems go beyond analysis to take corrective action automatically when appropriate, reducing manager workload and response time.

The system takes action without human intervention:

- Reroutes drivers around traffic automatically – Sends updated directions to driver navigation systems when congestion develops or accidents block routes

- Generates maintenance work orders – Creates repair tickets complete with diagnostic codes, symptoms, and scheduling recommendations when issues are detected

- Sends coaching alerts to managers – Notifies supervisors immediately when safety violations occur, with video evidence and recommended interventions

- Adjusts schedules for optimal efficiency – Rebalances workloads among drivers and vehicles based on real-time conditions and resource availability

Time Saved: 15-20 hours weekly in administrative tasks, managers focus on strategy and personnel development rather than constant crisis management

STEP 5: Continuous Learning

Unlike static software, AI-powered fleet management systems evolve and improve their performance over time through machine learning.

Every decision improves the system:

- Tracks outcome of every prediction – The system records whether predicted maintenance needs materialized, routes performed as expected, and recommendations proved correct

- Refines algorithms based on results – Machine learning models adjust their parameters to improve accuracy, learning from both successes and errors

- Adapts to your specific fleet characteristics – The AI develops an understanding of your unique operations, routes, vehicle mix, and business model

- Gets more accurate over time – Prediction accuracy and recommendation quality improve continuously as the system processes more of your fleet’s operational history

Result: Your fleet management system becomes customized to your operation, delivering insights and recommendations specifically tuned to your business rather than generic advice

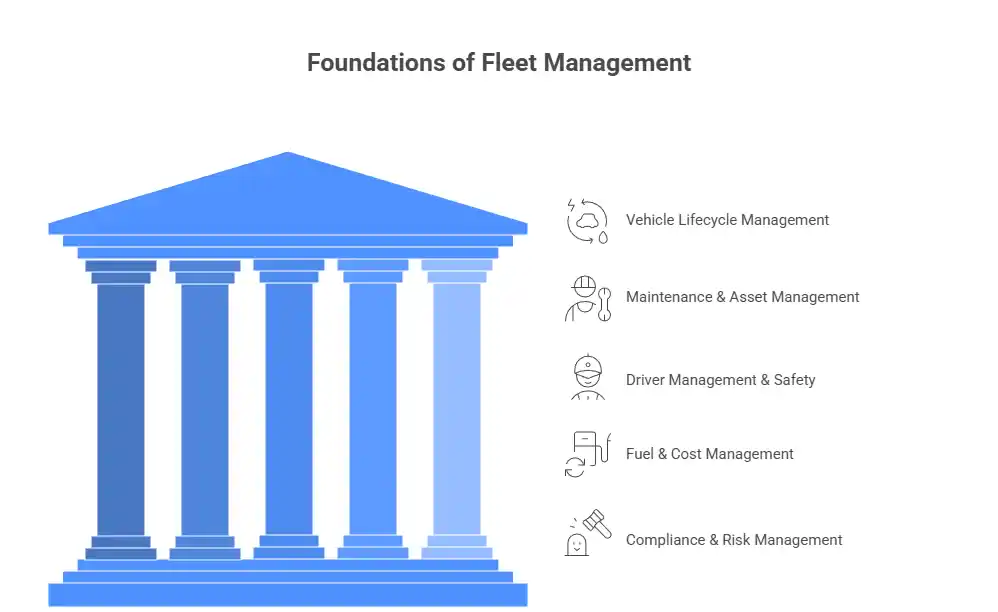

The 5 Pillars of Fleet Management

Understanding What Actually Matters

Think of your fleet management system as having five critical functions. Master these, and you master your fleet operations. Each pillar represents a major cost center and performance driver in fleet operations.

PILLAR 1: Vehicle Lifecycle Management

Strategic vehicle management extends far beyond simple procurement; it’s about optimizing the total cost of ownership across each vehicle’s entire lifespan.

The AI Advantage:

Your fleet management system analyzes comprehensive data that manual analysis cannot efficiently process.

- Total cost of ownership – Calculates actual costs, including purchase price, financing, insurance, fuel, maintenance, and depreciation over the projected lifespan

- Depreciation patterns – Tracks market values and resale trends to identify the sweet spot for replacement before value drops sharply

- Utilization rates – Identifies underutilized vehicles that could be redeployed, sold, or eliminated to improve overall fleet efficiency

- Maintenance history – Compares vehicles to determine which models, years, or configurations deliver the best long-term value

PILLAR 2: Maintenance & Asset Management

Maintenance represents your second-largest operating expense after fuel, making optimization critical to profitability and vehicle availability.

The AI Advantage:

Your fleet management system shifts from reactive repairs to proactive maintenance based on actual vehicle condition.

- Condition-based servicing – Services vehicles based on actual wear and performance data rather than arbitrary mileage or time intervals

- Failure prediction – Identifies patterns indicating potential failures before breakdowns occur, preventing costly emergency repairs

- Optimal maintenance timing – Determines the most cost-effective moment for service that balances vehicle availability with repair costs

- Automated compliance tracking – Ensures all required inspections and services are completed on schedule without manual oversight

PILLAR 3: Driver Management & Safety

Drivers are your most valuable asset and your greatest risk factor. This pillar focuses on maximizing their performance while minimizing liability exposure.

The AI Advantage:

Your fleet management system creates a continuous improvement loop that reduces accidents and liability while improving efficiency.

- Real-time risk detection – Identifies dangerous behaviors as they happen, enabling immediate intervention before accidents occur

- Predictive safety scoring – Analyzes patterns to identify high-risk drivers before they cause incidents, reducing accident rates

- Automated coaching workflows – Triggers alerts to managers and delivers targeted training based on specific driver behaviors without manual review

- Progress tracking – Monitors improvement over time to verify coaching effectiveness and identify drivers needing additional support

PILLAR 4: Fuel & Cost Management

Fuel expenses represent the largest controllable operating cost for most fleets, making even small percentage improvements highly valuable.

The AI Advantage:

Your fleet management system identifies and eliminates every source of fuel waste across your operation, typically saving 15-25% in the first year.

- Intelligent route planning – Creates routes considering distance, traffic, elevation changes, and stops to balance time and fuel efficiency

- Targeted driver coaching – Focuses on specific high-impact behaviors like idling reduction and smooth acceleration that directly cut consumption

- Right-sizing recommendations – Matches vehicle capacity to actual load requirements, avoiding oversized vehicles on light deliveries

- Strategic fuel purchasing – Analyzes market trends and regional price variations to optimize fueling locations and timing, saving thousands annually

PILLAR 5: Compliance & Risk Management

Regulatory compliance is non-negotiable in commercial fleet operations, with violations resulting in fines, shutdowns, and permanent record impacts.

The AI Advantage:

Your fleet management system transforms compliance from a time-consuming administrative burden into an automated, proactive process.

- Automated compliance tracking – Monitors all regulatory requirements and maintains instantly accessible digital records for audits

- Proactive violation alerts – Sends real-time notifications when drivers approach HOS limits, inspections come due, or certifications near expiration

- Centralized digital records – Eliminates paper logs and filing cabinets with secure cloud storage for better organization and retrieval

- Pre-audit gap analysis – Generates compliance summaries identifying any issues before official inspections, allowing corrective action

Conclusion: Your Next Steps

AI-powered fleet management systems are essential for staying competitive in 2026. The technology is proven, implementation is straightforward, and your competitors are already gaining advantages through optimized operations, reduced costs, and superior customer service. The question isn’t whether you can afford to implement, it’s whether you can afford to wait while others pull ahead. The future of fleet management is here, powered by AI, and your journey toward intelligent operations starts today.

FAQ

What is a fleet management system?

A fleet management system uses AI, GPS, and telematics to monitor and optimize vehicle operations in real-time. It tracks location, driver behavior, fuel usage, and maintenance needs, helping businesses reduce costs and improve efficiency.

What is an example of fleet management?

A delivery company with 50 trucks uses the system to track vehicle locations, monitor driver safety, optimize routes to save fuel, schedule preventive maintenance, and ensure compliance with regulations all from a single dashboard with automated alerts.

What are the 5 pillars of fleet management?

1. Vehicle Lifecycle Management, 2. Maintenance & Asset Management, 3. Driver Management & Safety, 4. Fuel & Cost Management, 5. Compliance & Risk Management.

What is ERP in fleet management?

ERP in fleet management is an integrated software system that connects fleet operations with other business functions like finance, procurement, and inventory, centralizing all data into one unified platform for streamlined operations and better decision-making.

How can I reduce my fleet’s fuel costs?

By using idle time monitoring, route optimization, and tracking driver behaviors like speeding and harsh acceleration.

Is fleet management software easy to use?

Most platforms feature intuitive dashboards and are designed to be user-friendly with minimal training required.

How secure is my fleet data?

Fleet data is protected through encrypted cloud storage, secure data centers, and industry-standard security protocols.