Table of Contents

IoT-Enabled Controlled Environment Agriculture

The global food industry is undergoing a quiet but powerful revolution, one driven not by bigger farms, but by smarter ones. At the heart of this transformation lies the concept of controlled environment agriculture (CEA), a method of growing crops where every variable-light, water, temperature, and humidity is precisely managed.

But managing a controlled environment manually is neither scalable nor efficient. This is where the Internet of Things (IoT) steps in. IoT-enabled CEA systems use networks of sensors, microcontrollers, and cloud platforms to monitor, automate, and optimize every aspect of indoor and greenhouse farming.

This article breaks down exactly how IoT is enhancing controlled environment agriculture, from the architecture behind these systems to the sensors that power them, and why this integration is reshaping the future of food production.

Why This Matters Now

- The global population is projected to reach 9.7 billion by 2050

- Traditional farming accounts for 70% of global freshwater use

- Climate change is making conventional agriculture increasingly unpredictable

- Urbanization is reducing available farmland worldwide

IoT-enabled controlled environments address all four of these challenges simultaneously.

What Is Controlled Environment Agriculture (CEA)?

Controlled environment agriculture is an umbrella term for any farming method where growing conditions are artificially regulated to optimize crop growth. Unlike traditional open-field farming, CEA gives growers full command over the variables that affect plant health and yield.

Types of Controlled Environment Agriculture

| Type | Description | Key Feature |

| Vertical Farming | Crops grown in stacked layers indoors | Maximizes space in urban settings |

| Greenhouses | Enclosed structures with natural or artificial light | Semi-controlled environment with lower energy costs |

| Hydroponic Systems | Plants grown in nutrient-rich water without soil | Up to 90% less water than traditional farming |

| Aeroponic Systems | Plant roots suspended in air and misted with nutrients | Fastest growth rate among soilless methods |

| Aquaponic Systems | Combines fish farming with plant cultivation | Closed-loop, sustainable ecosystem |

What Makes CEA Different?

In a controlled environment, farmers replace guesswork with data. Instead of hoping for rain, they schedule irrigation. Instead of waiting for sunlight, they program LED grow lights. This precision is what makes IoT integration so powerful in CEA. The system already demands control; IoT simply makes that control intelligent and automated.

IoT Architecture for CEA Systems

A well-designed IoT architecture is the backbone of any smart-controlled environment. It consists of four interconnected layers that work together to collect, transmit, process, and act on real-time agricultural data.

The Four-Layer IoT Architecture

| Layer | Layer Name | Key Components | Role in Controlled Environment |

|---|---|---|---|

| Layer 1 | Perception Layer | Sensors, Actuators, Microcontrollers (ESP32, Arduino) | Where data is born sensors collect real-time information on temperature, humidity, light, and soil moisture across the controlled environment |

| Layer 2 | Network / Communication Layer | LoRaWAN, MQTT, Wi-Fi, Zigbee | Transfers data from sensors to the cloud; LoRaWAN is ideal for large greenhouses due to its long range and low power consumption |

| Layer 3 | Cloud / Fog Layer | AWS IoT, Google Cloud, ThingSpeak, Edge Computing | Stores, processes, and analyzes the collected data; edge computing can process data locally to reduce latency |

| Layer 4 | Application Layer | Dashboards, Mobile Apps, Alert Systems | End users monitor and manage the controlled environment here instant alerts are sent if any parameter goes out of range |

Layer Breakdown

Perception Layer: This is where data is born. Sensors planted across the controlled environment collect information about temperature, humidity, light, soil moisture, and more. Microcontrollers like the ESP32 or Arduino act as the local brain, reading sensor values and preparing them for transmission.

Network/Communication Layer: Data travels from sensors to the cloud through communication protocols. LoRaWAN is ideal for large greenhouses due to its long range and low power consumption. MQTT is a lightweight messaging protocol commonly used for IoT-to-cloud communication. Wi-Fi and Zigbee handle short-range indoor connectivity.

Cloud/Fog Layer: Once data reaches the cloud (platforms like AWS IoT, Google Cloud, or ThingSpeak), it is stored, processed, and analyzed. Edge or fog computing can also process data locally to reduce latency.

Application Layer: End users interact with the system through dashboards, mobile apps, and alert systems. If a temperature spike is detected in the controlled environment, an alert is sent instantly to the farmer’s phone.

Architecture Comparison

| Architecture Type | Latency | Cost | Best For |

| Cloud-Based | Medium | Higher | Large-scale operations needing deep analytics |

| Edge/Fog Computing | Low | Medium | Time-sensitive decisions in real-time |

| Hybrid | Low–Medium | Medium–High | Balancing real-time control with deep analysis |

Key Components and Sensors

Sensors are the eyes and ears of any controlled environment system. They provide the real-time data that drives every automated decision.

Essential Sensors in CEA

| Sensor | Parameter Measured | Role in Controlled Environment |

| Temperature Sensor (DHT22, DS18B20) | Air/soil temperature | Maintains optimal growth temperature |

| Humidity Sensor (DHT22, SHT31) | Relative humidity | Prevents mold; regulates transpiration |

| Light/PAR Sensor | Photosynthetically Active Radiation | Ensures plants receive the right light spectrum and intensity |

| CO₂ Sensor (NDIR) | Carbon dioxide concentration | Optimizes photosynthesis by controlling CO₂ levels |

| EC Sensor | Electrical conductivity of nutrient solution | Monitors nutrient strength in hydroponic systems |

| pH Sensor | Acidity/alkalinity of water or soil | Ensures nutrients are bioavailable to plants |

| Water Flow Sensor | Volume of water moving through the system | Tracks irrigation efficiency and detects leaks |

| Light Timer/Relay | On/Off scheduling | Automates LED grow light cycles |

Microcontrollers and Edge Devices

| Device | Key Specs | Use Case |

| Arduino Uno | Basic GPIO, low cost | Simple single-sensor monitoring |

| ESP32 | Wi-Fi + Bluetooth, dual-core | Multi-sensor nodes with wireless connectivity |

| Raspberry Pi | Full Linux OS, high processing power | Edge computing and local data processing |

| LoRa Module (SX1276) | Long-range, low-power radio | Transmitting data across large greenhouse areas |

How Components Work Together

In a typical setup, multiple sensor nodes are spread across the controlled environment. Each node collects data using 2–4 sensors, processes it locally on a microcontroller, and transmits it wirelessly to a central hub or directly to the cloud. Actuators, such as fans, pumps, and lights, receive commands based on the processed data, creating a seamless, automatic feedback loop.

Smart Greenhouse Automation and Control in CEA

Automation is what transforms a controlled environment from a passively maintained space into an actively intelligent one. IoT-based automation systems use sensor data to trigger real-time actions without human intervention.

What Gets Automated?

| System | Automation Action | Trigger Condition |

| Irrigation | Pumps activate to water plants | Soil moisture drops below the threshold |

| Lighting | LED grow lights adjust spectrum and intensity | The light sensor reads below the PAR target or the time-based schedule |

| Ventilation | Fans or vents open/close | Temperature or humidity exceeds set limits |

| Nutrient Delivery | Dosing pumps add nutrients to water | EC sensor reads below the optimal level |

| CO₂ Management | CO₂ injector activates | CO₂ concentration drops below the photosynthesis optimum |

| Climate Control | HVAC or heating system, activates | Temperature drops below the minimum threshold |

Closed-Loop Control Systems

The most effective smart greenhouses use closed-loop control, a system where the output (e.g., temperature) is continuously monitored and fed back to adjust the input (e.g., heater setting). This creates a self-correcting cycle that keeps every parameter within the ideal range for crops.

How it works in a controlled environment:

- Sense: A sensor reads the current value (e.g., humidity at 80%)

- Compare: The system compares it to the target value (e.g., ideal humidity = 60%)

- Decide: A controller calculates the required adjustment

- Act: An actuator executes the change (e.g., the fan turns on)

- Repeat: The loop runs continuously, often every few seconds

Real-World Example

A vertical farm in a controlled environment uses ESP32 nodes equipped with humidity and temperature sensors. When humidity exceeds 65%, the system automatically activates exhaust fans and adjusts the HVAC. Simultaneously, a mobile dashboard notifies the farm manager, and the event is logged for future AI-based analysis.

Data Analytics and Artificial Intelligence in CEA

Raw sensor data is valuable, but the real power comes from turning that data into insights. AI and analytics transform the controlled environment into a learning system that gets smarter over time.

Types of Analytics in CEA

| Analytics Type | What It Does | Example |

| Descriptive | Reports what has happened | “Temperature averaged 24°C this week” |

| Diagnostic | Explains why something happened | “Yield dropped because light intensity was 15% below target” |

| Predictive | Forecasts what will happen | “At current growth rates, harvest is expected in 12 days” |

| Prescriptive | Recommends what to do | “Increase nitrogen dosage by 10% to optimize leaf growth” |

AI Applications in Controlled Environments

- Crop Health Monitoring: Computer vision systems use cameras and machine learning to detect diseases, pests, or nutrient deficiencies early, often before they are visible to the human eye.

- Yield Prediction: AI models trained on historical data from the controlled environment can predict crop yields with high accuracy, helping farmers plan harvests and supply chains.

- Energy Optimization: Machine learning algorithms analyze lighting, heating, and ventilation patterns to reduce energy consumption while maintaining ideal growing conditions, a critical factor in the cost efficiency of controlled environment agriculture.

- Automated Nutrient Management: AI systems monitor plant uptake rates and water chemistry in real time, automatically adjusting nutrient formulas to match each growth stage.

AI vs. Rule-Based Automation

| Feature | Rule-Based System | AI-Powered System |

| Decision-Making | Fixed “if-then” rules | Learns and adapts from data |

| Complexity Handling | Limited to predefined scenarios | Handles complex, multi-variable situations |

| Accuracy Over Time | Stays constant | Improves with more data |

| Setup | Manual configuration | Requires training data and model tuning |

Challenges and Future Directions

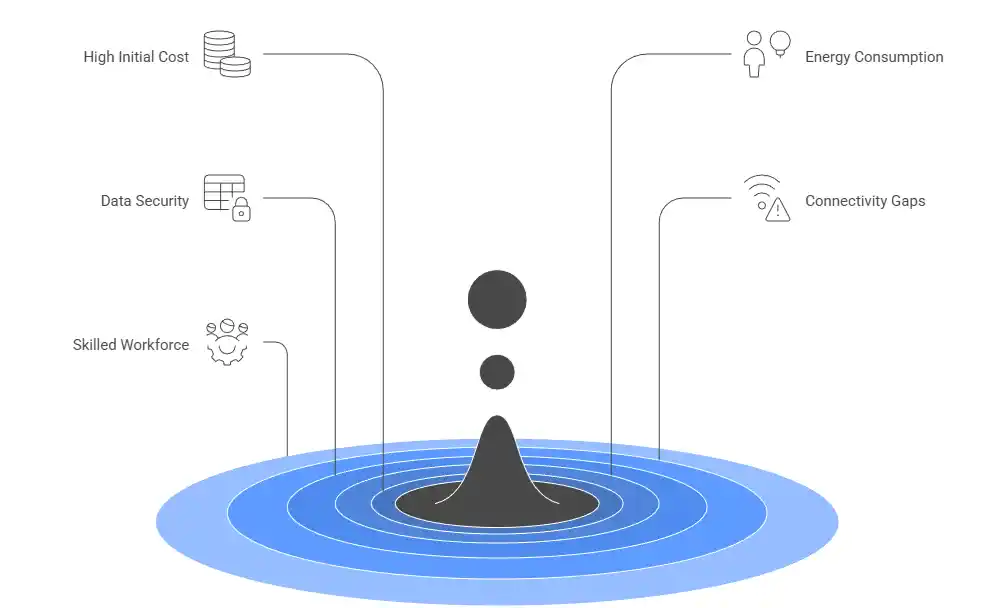

Despite its enormous potential, IoT-enabled controlled environment agriculture is not without obstacles. Understanding these challenges is key to accelerating adoption.

Current Challenges

- High Initial Cost: Setting up a fully IoT-integrated controlled environment requires investment in sensors, microcontrollers, cloud infrastructure, and connectivity, which can be a barrier for small-scale farmers.

- Energy Consumption: Vertical farms and fully enclosed greenhouses rely heavily on artificial lighting and climate control, making energy costs a significant operational expense.

- Data Security and Privacy: Connected agricultural systems are potential targets for cyberattacks. Ensuring secure data transmission and storage is critical.

- Connectivity Gaps: Reliable internet access is essential for cloud-based IoT systems, but many rural and remote areas still lack adequate infrastructure.

- Skilled Workforce: Operating and maintaining IoT systems requires technical knowledge that is often scarce in traditional farming communities.

Emerging Solutions

| Challenge | Emerging Solution |

| High cost | Declining sensor prices; open-source hardware (Arduino, ESP32) |

| Energy use | Solar-powered systems; energy-efficient LED lighting |

| Security | Blockchain-based data integrity; edge-level encryption |

| Connectivity | 5G rollout; LoRaWAN for low-power, long-range coverage |

| Workforce | Online training platforms; plug-and-play IoT kits |

Future Directions

- Digital Twins: Virtual replicas of physical controlled environments that simulate and predict outcomes before changes are made

- Drone Integration: Autonomous drones for monitoring and pollination inside large greenhouses

- Blockchain Traceability: End-to-end tracking of produce from the controlled environment to the consumer’s plate

- Robotics: Automated planting, harvesting, and maintenance robots that work alongside IoT systems

Conclusion

IoT is not just an add-on to controlled environment agriculture; it is becoming the foundation upon which modern CEA is built. By enabling real-time monitoring, intelligent automation, predictive analytics, and AI-driven decision-making, IoT transforms the controlled environment into a precision farming powerhouse

FAQs

What is controlled environment agriculture?

Controlled environment agriculture (CEA) is a farming approach that optimizes plant growth by precisely regulating temperature, light, humidity, and nutrients.

How does IoT work in agriculture?

IoT in agriculture uses sensors, cloud platforms, and automated controls to monitor conditions and optimize farming operations in real time.

What sensors are most important in a controlled environment?

Key sensors include temperature, humidity, light, CO₂, pH, EC, and water flow sensors for precise environmental control.

Is IoT-based farming expensive?

While initial setup costs exist, IoT-based farming lowers long-term expenses through automation, efficiency, and reduced resource waste.

Can small-scale farmers use IoT in CEA?

Yes, scalable and open-source IoT solutions make controlled environment farming affordable for small-scale growers.

How does AI improve controlled environment agriculture?

AI enhances controlled environment agriculture by enabling predictive analytics, crop health monitoring, and automated resource optimization.

What communication protocols are used in CEA IoT systems?

CEA IoT systems commonly use LoRaWAN, MQTT, Wi-Fi, and Zigbee for reliable sensor data transmission.

What is the future of controlled environment agriculture?

The future of controlled environment agriculture lies in fully autonomous farms powered by IoT, AI, robotics, and digital twins.