Table of Contents

Understanding AI Inventory Management

Did you know that businesses using AI in inventory management can reduce costs by up to 20%?

An effective AI inventory management system is important for any company hoping to succeed in a competitive marketplace.

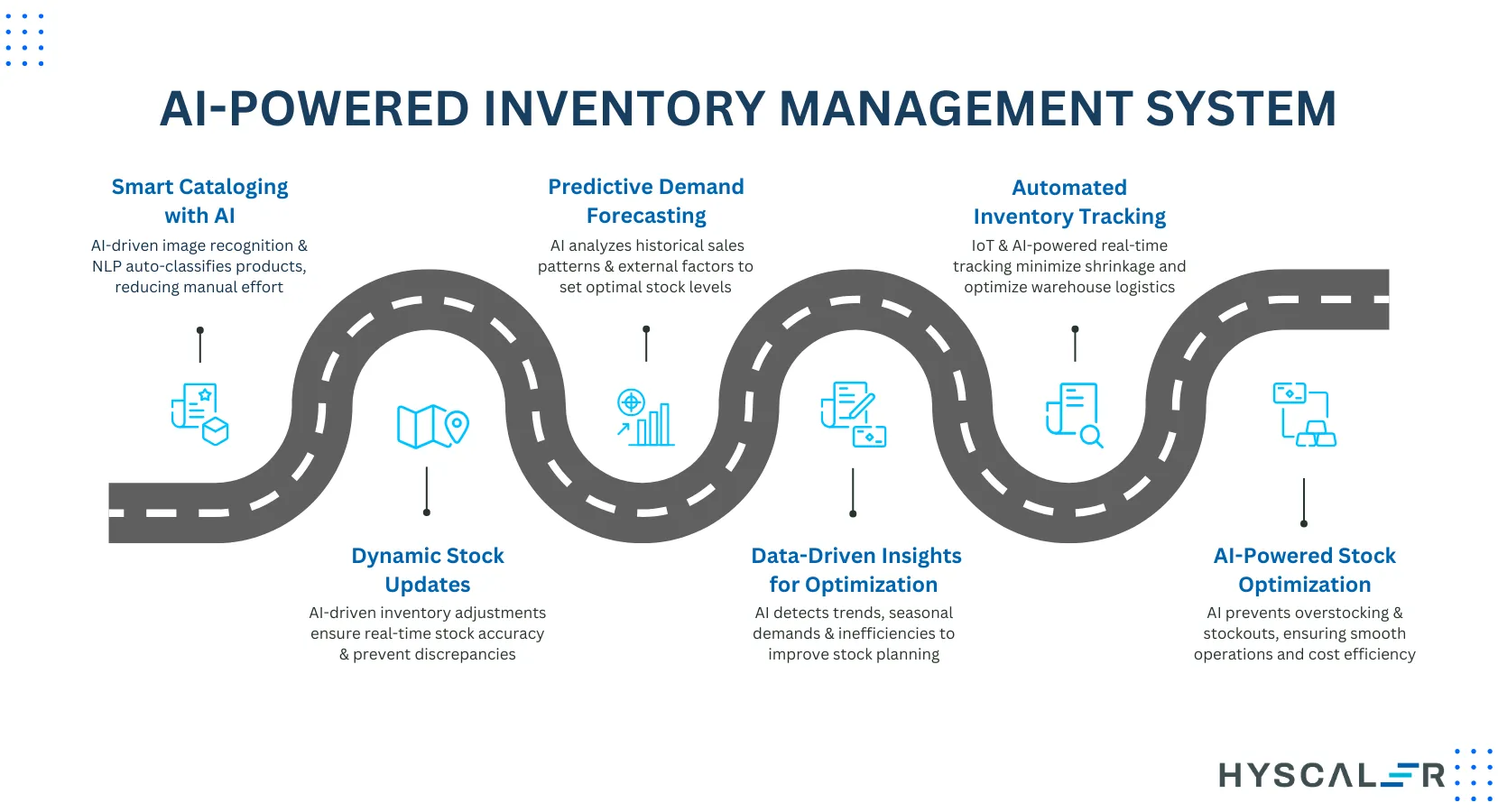

Enter AI inventory management systems, which leverage advanced technology to automate and improve inventory functions. But what sets these systems apart?

Conventional inventory management systems tend to rely on human monitoring, but AI extends this method further.

By combining data analysis, machine learning, and predictive analysis, these systems improve key functions such as forecasting demand and managing suppliers.

Ponder having the ability to forecast customer demand at a rate of up to 95% accuracy—how would that revolutionize your operations?

True magic happens through inventory optimization. Companies can keep the optimal level of stock with the lowest possible holding costs and therefore achieve the highest profitability.

Firms using AI-based inventory management systems are likely to realize impressive gains in efficiency, up to 30-50% decrease in the time taken to accomplish inventory work, for example.

Interested to learn how this technology can transform your inventory management? Let’s explore its primary features and advantages in more detail.

Critical Use Cases of AI Inventory Management Systems

Inventory management systems using AI provide numerous revolutionary features meant to significantly boost operations. The following are some of the essential use cases for AI in inventory management systems:

Demand Forecasting

AI transforms demand forecasting in inventory management systems by allowing businesses to react dynamically to changes in the market.

Using machine learning algorithms, companies obtain more insights into customer behavior and patterns of demand. This accuracy in forecasting enables real-time adjustment of stock levels, reducing the risk of stockouts or overstocking.

Real-time Visibility

AI provides greater visibility into inventory locations and conditions throughout the supply chain, a key feature of inventory management systems.

Through integration with the Internet of Things (IoT), companies can track stock levels and supply chain health in real-time through sensor-enabled inventory items that produce vast amounts of data.

Anomaly Detection

AI is strong in detecting discrepancies in inventory quantities or sales patterns in inventory management systems.

Large datasets are studied by machine learning algorithms to look for anomalies indicating theft, mistake, or interference, enabling timely responses to help keep operations in check.

Supplier Management

AI-based analytics tools automate supplier management in inventory management systems through performance metrics analysis such as delivery times and quality.

Business intelligence derived from such data helps organizations select good suppliers and negotiate the best terms.

Scenario Simulation

Scenario simulation tools within inventory management systems enable companies to simulate different market conditions and analyze their potential effects on inventory.

Preparing for demand fluctuations helps organizations change strategies rapidly according to changing conditions.

Automated Replenishment

Automated stock replenishment systems in inventory management systems track inventory levels in real time, ordering automatically when levels dip below set points.

This practice ensures product availability while minimizing the cost of excess inventory.

Warehouse Operations

Inventory management systems, AI Inventory management, Inventory Optimization and AI tools maximize warehouse layout and fulfillment processes through the analysis of product attributes and demand patterns, which are essential roles of inventory management systems.

Efficient storage configuration recommendations result in streamlined operations, inventory optimization, and shorter lead times.

Alert Management

AI solutions deliver predictive warnings of critical inventory levels or differences within inventory management systems to prompt responses before problems occur.

This supports total inventory accuracy and avoids stockouts or overages.

Inventory Tracking

High-level tracking in inventory management systems allows for real-time monitoring of inventory movement in many locations, providing information about availability and turnover rates of stocks using an indoor positioning system to precisely locate items within warehouses and facilities.

Reporting and Analytics

Detailed reports produced by AI in inventory management systems provide in-depth analysis of inventory performance, trends, and inefficiencies, which enable managers to make strategic decisions.

Inventory Segmentation

Inventory segmentation methods, including ABC analysis, are part of inventory management systems.

These methods enable companies to classify products according to demand patterns, shelf life, and profitability.

This focused approach enables customized management strategies. For example, high-demand, short-shelf-life items such as perishables need to be managed differently than slow-moving, long-lasting items such as furniture.

AI guarantees that the correct products get the correct attention, maximizing time and resources.

Through the integration of multiple segmentation approaches, companies can develop a dynamic and responsive inventory management system that adjusts with fluctuating market trends and customer demands.

System Integration

Smooth integration into inventory management systems ensures smooth data transfer between inventory management and other company functions, ensuring accuracy and keeping overall business strategy in line.

Why AI is Revolutionizing Inventory Management System

Benefits of AI in Inventory Management System

AI is revolutionizing the age-old inventory management system, making it achieve tremendous leaps in operational effectiveness and strategic decisions. Below are some of the major advantages:

Data Structuring and Analysis

One of the great challenges for organizations today is addressing the huge quantities of unstructured data that the inventories within their companies are producing.

AI is best-positioned to rectify this dilemma at scale through cleaning and organizing data so companies can focus on meaningful insights upon which to focus analysis, predictions, reporting, and decision-making.

Rich insight enables organizations to make well-considered, smart decisions optimizing inventory and supply chain, in turn fueling strategic business expansion.

Improved Accuracy

Sophisticated algorithms are designed to scan massive data sets to provide accurate demand forecasts.

These AI-based insights can dramatically minimize human error-led stockouts and overstock situations.

As per McKinsey, businesses applying AI to inventory management system have an accuracy level of up to 95% when it comes to demand forecasting, thereby minimizing supply chain unreliability.

Cost Savings

AI optimizes inventory levels by reducing excess stock and eliminating inefficiencies in the supply chain.

This directly results in lower carrying costs. Companies can reduce storage costs by up to 20% by implementing efficient inventory management practices, according to a Deloitte study.

Increased Efficiency

By automating repetitive processes such as inventory management and reordering, companies save precious time for employees to work on strategic projects.

A Gartner research revealed that companies using automation are able to enhance operational effectiveness by 30%, highlighting the worth of AI in process automation.

Enhanced Customer Satisfaction

AI inventory management systems make the right products available at the right time, and this improves customer satisfaction & inventory optimization.

According to Accenture research, companies that use AI-based insights for on-time product availability can boost customer retention rates by as much as 15%.

Scalability

Artificial intelligence-based systems can easily keep pace with expanding inventories and changing market trends, allowing businesses to expand operations without compromising on efficiency.

Flexibility is essential for companies interested in leveraging changing demands.

Decision-Making with Insights

Utilizing real-time data analysis, AI provides decision-makers with usable insights, leading to timely and informed decisions.

Organizations that deploy AI for managing inventories are able to enhance strategic results by 20-25%, says a BCG report.

Overcoming Common Challenges with AI Technology

Although AI delivers many advantages to inventory management systems, it also offers some challenges that organizations need to overcome:

Data Issues

AI is dependent on good-quality data to deliver accurate results.

Poor-quality, out-of-date, or partial data can result in poor-quality predictions and suboptimal decisions. Organizations usually grapple with large volumes of data across various systems, which creates data silos.

Combing these sources can be challenging and time-consuming, but it is vital for delivering maximum AI performance.

Resistance to Change

Staff can be resistant to implementing new technologies, and this can inhibit rollout.

A successful resolution of this challenge necessitates proper change management measures such as communication and thorough training schemes to enable seamless transition.

First-Time Costs

The first-time investment in AI technologies—i.e., purchasing software, integration, and staff training—can be considerable.

This may create a problem for small firms. Yet the payback period often overrules initial outlay costs.

Security and Compliance Issues

The greater dependence on information creates important concerns regarding privacy and security.

Enterprises need to make certain their AI-driven inventory systems are in line with applicable regulations and sufficiently safeguard sensitive data. This is vital for upholding customer confidence and preserving business reputation.

By knowing these advantages and issues, organizations are able to make informed decisions on whether or not to implement AI in their inventory management systems, ultimately using the technology to improve performance and achieve a competitive advantage.

Selecting the Right Inventory Management System Software

“Hey, Alexa, can you take care of my inventory for me?” While this sounds like something straight out of science fiction, AI-enabled tools are transforming the way we manage inventory.

With such advanced technologies, companies can optimize stock levels, anticipate shortages, and prevent overstocking.

Actually, with the use of AI, companies can achieve a 15% cost reduction in logistics, along with increases in inventory and service levels of 35% and 65%, respectively.

Key Features to Look Out for

When looking for an AI inventory management solution, ensure that you look out for these key functionalities:

Demand Forecasting: Ensure the software is able to analyze previous sales history and market trends to make accurate projections of future demand.

Inventory Optimization: Look for features that provide insights into your inventory levels to ensure you have the right products in the right quantities.

Integration with Existing Systems: Confirm that the solution will integrate with your ERP, POS, and warehouse management systems.

Automation Capabilities: Select systems that will automate repetitive inventory processes such as order creation and low-stock notifications.

Scalability and Flexibility: Select tools that can scale with your business and adjust to your specific requirements.

Multi-Location Inventory Management: Ensure that there is support for aggregating inventory management across multiple locations.

AI-Driven Insights: Seek capabilities that inspect customer behavior and supplier performance for actionable insights.

Assess Your Current Warehouse Inventory Management system

Start by assessing your current inventory systems.

Knowing your operational deficiencies can inform your search for the appropriate inventory management system:

- Determine what items are constantly overstocked or continually out of stock.

- Determine if tracking shelf life is necessary for perishable items.

- Review historical sales data to reveal trends in demand.

Establish Inventory Management Objectives

With knowledge of your inventory past, establish realistic objectives for your inventory management system:

Establish optimal levels and re-order points to match supply and demand without putting cash flow under too much pressure.

Define needed “safety stock” on top sellers and places to reduce slow-moving inventory.

Apply key statistics such as:

Inventory Turnover Ratio: Gives an indication of how fast stock is selling.

Carrying Costs: A measure of the costs associated with carrying inventory.

Fill Rates: Indicates the ratio of orders filled from on-hand inventory.

Research Multiple Vendors

Research multiple vendors to locate an inventory management system that fits your objectives. Look for systems with the following features:

Sales Forecasting: Minimizes overstocking and stockouts, increasing customer order fulfillment rates.

Real-time Tracking: Enables rapid responses to spikes in demand, allowing you to replenish stock effectively.

Workflow Automation: Sets up AI programs to automate reorder when stock levels deplete.

Customization Options: Enables you to create dashboards that highlight essential inventory metrics specific to your requirements.

Reporting & Insights: Monitors performance against KPIs in real-time and provides AI-driven recommendations for improvement.

Integrations: Integrates with CRM systems and e-commerce sites to give you a view of data in one place.

Scalability: Scales with your business, managing increased product lines and data complexity efficiently.

By carefully weighing these characteristics and adhering to the steps laid out, you can make a confident choice of the appropriate inventory management system that improves efficiency and meets your business objectives.

Inventory Management System: AI’s Razor Edge

C3 AI: The Oracle.

- Predicts demand with AI precision.

- “What-if” scenarios, no more guessing.

- Massive SKU mastery.

Peak AI: The Tailor.

- Custom-fit inventory, like a bespoke suit.

- Forecasts demand, optimizes safety stock.

- Seamlessly weaves into your business.

Blue Yonder: The Maestro.

- Orchestrates the warehouse with real-time vision.

- Machine learning, cutting waste, boosting flow.

- Replenishment, perfected.

DEAR Inventory: The Automator.

- Syncs with Xero/QuickBooks, kills manual drudgery.

- B2B portal, empowers customers.

- Automation rules, across your empire.

Zoho Inventory: The Agile Ally – Inventory Management system for small business

- Barcode precision, stockout alerts.

- Dropshipping, rides the sales wave.

- User-friendly, empowers growth.

Inventory Management System: The Unseen Advantage – HyScaler’s Gamble

Forget spreadsheets. Forget “gut feeling.” HyScaler’s Inventory Management System isn’t monitoring; it’s observing.

The Oracle Within: AI murmurs forecasts, not hypotheses. Stock notifications? Easy peasy. HyScaler recommends—before you even pose the question.

The Fortress: Locked-down onboarding, device tracking, compliance under lock and key. Single point of view. No breaches.

The Choreographer: Eliminates the tedium. Tasks delegated, workflows choreographed. No more repetitive drudgery.

The Storyteller: Data is more than numbers. It’s wisdom. Strong reports, simple narratives. Recognize the trends, claim the future.

The Visualizer: List, Board, Calendar—your stock, your way. See it, touch it, own it.

The Integrator: Smooth integration with your current systems, because your data should run, not halt.

The Optimizer: AI-driven recommendations to maximize your supply chain, lowering waste and lifting profits.

The Guardian: Monitor expiration dates, and receive AI driven recommendations to turn stock, reducing loss.

End reacting. Begin anticipating. HyScaler’s Inventory Management System is your behind-the-scenes edge.

Ready to discover what your inventory can be?