Table of Contents

The manufacturing landscape is experiencing its most significant transformation in decades. While traditional manufacturers struggle with outdated systems and operational inefficiencies, forward-thinking companies are leveraging cloud manufacturing software to achieve remarkable results.

The numbers tell a compelling story: Cloud Manufacturing Market size is estimated to reach USD $200 billion by 2030, growing at a CAGR of 16.1% during the forecast period 2023-2030. The Cloud Manufacturing Software Market stood at USD 10.5 billion in 2024 and is projected to attain USD 28.3 billion by 2033, with a steady CAGR of 14.8%.

But here’s what really matters for your business: 34% of manufacturers already see ROI from AI, with 92% viewing smart manufacturing as a future differentiator for investors. Early adopters aren’t just keeping pace – they’re setting the new standard for operational excellence.

If you’re still relying on legacy systems, spreadsheets, or disconnected software solutions, you’re not just missing opportunities – you’re actively falling behind competitors who are already reaping the benefits of cloud-powered manufacturing operations.

What Exactly is Cloud Manufacturing Software? (And Why It’s Your Competitive Advantage)

Cloud manufacturing software isn’t just another tech trend. It’s a complete operational philosophy that transforms how you manage every aspect of your manufacturing business.

At its core, cloud manufacturing software is:

- A comprehensive suite of integrated applications hosted on a secure cloud infrastructure

- Real-time management of production, inventory, quality, and supply chain operations

- Seamless connectivity between your shop floor, office, and external partners

- Scalable solutions that grow with your business without massive infrastructure investments

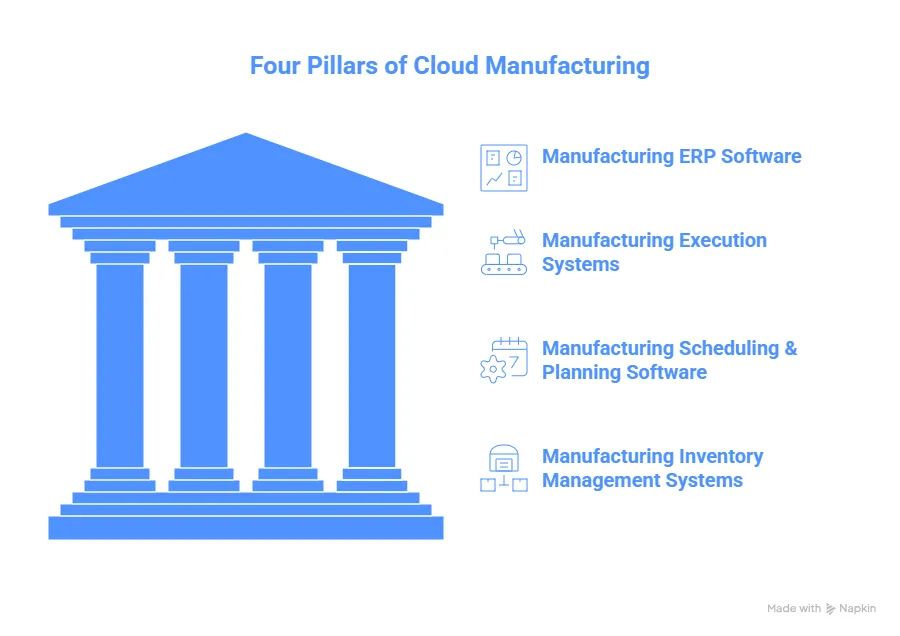

The Four Pillars of Cloud Manufacturing Excellence

1. Manufacturing ERP Software (Enterprise Resource Planning): Your operational command center that unifies financial management, supply chain coordination, human resources, and business intelligence into a single, powerful platform.

2. Manufacturing Execution Systems (MES): The real-time bridge between your planning systems and shop floor operations, providing instant visibility into production status, quality metrics, and performance indicators.

3. Manufacturing Scheduling & Planning Software: Advanced algorithms that optimize production schedules, resource allocation, and capacity planning to maximize throughput while minimizing costs.

4. Manufacturing Inventory Management Systems: Smart inventory control that predicts demand, automates reordering, and maintains optimal stock levels across multiple locations.

The Cloud Difference: Unlike traditional on-premise solutions, cloud manufacturing software delivers these capabilities through secure internet connections, enabling real-time access from anywhere, automatic updates, and seamless scalability without hardware investments.

Cloud Manufacturing Software Solutions: Choose Your Path to Success

Enterprise Resource Planning (ERP) Solutions

SAP S/4HANA Cloud

- Best for: Large enterprises seeking comprehensive digital transformation

- Key strengths: Advanced analytics, AI-powered insights, real-time reporting

- Ideal scenarios: Multi-location operations, complex supply chains, regulatory compliance requirements

Oracle NetSuite ERP

- Best for: Growing manufacturers needing scalable financial management

- Key strengths: Multi-subsidiary management, comprehensive accounting, CRM integration

- Ideal scenarios: Rapid business growth, acquisition integration, global operations

Microsoft Dynamics 365 for Manufacturing

- Best for: Microsoft ecosystem companies wanting seamless integration

- Key strengths: Power Platform integration, familiar Office interface, AI capabilities

- Ideal scenarios: Existing Microsoft users, custom workflow requirements, hybrid cloud deployments

Manufacturing Execution Systems (MES)

Siemens Opcenter Execution

- Best for: Process manufacturers requiring detailed traceability

- Key strengths: Real-time production control, quality management, regulatory compliance

- Ideal scenarios: Pharmaceutical, food & beverage, chemical manufacturing

Rockwell Automation FactoryTalk ProductionCentre

- Best for: Discrete manufacturers with complex assembly processes

- Key strengths: Equipment integration, performance analytics, maintenance management

- Ideal scenarios: Automotive, aerospace, industrial equipment manufacturing

Production Planning & Scheduling

PlanetTogether Advanced Planning & Scheduling (APS)

- Best for: Manufacturers with complex scheduling challenges

- Key strengths: Finite capacity scheduling, constraint-based planning, what-if analysis

- Ideal scenarios: Make-to-order operations, resource-constrained environments

Preactor Scheduling Software

- Best for: Job shop and batch manufacturers

- Key strengths: Drag-and-drop scheduling, real-time optimization, integration flexibility

- Ideal scenarios: Custom manufacturing, mixed-mode production

Inventory Management Solutions

Fishbowl Manufacturing

- Best for: SME manufacturers needing integrated inventory and production control

- Key strengths: Bill of materials management, work order tracking, QuickBooks integration

- Ideal scenarios: Growing manufacturers, multi-location inventory, job costing requirements

Katana Manufacturing ERP

- Best for: Modern manufacturers seeking user-friendly cloud solutions

- Key strengths: Visual production planning, real-time inventory tracking, e-commerce integration

- Ideal scenarios: Consumer goods, craft manufacturing, direct-to-consumer operations

Cloud vs. On-Premise: The Business Case That Writes Itself

The Total Cost Reality Check

Cloud Manufacturing Software:

- Initial Investment: $50-500 per user/month

- Implementation Time: 3-6 months

- Maintenance Costs: Included in subscription

- Upgrade Costs: Automatic and included

- IT Staff Requirements: Minimal

On-Premise Solutions:

- Initial Investment: $50,000-$500,000+ in licenses and hardware

- Implementation Time: 6-18 months

- Annual Maintenance: 15-22% of license cost

- Upgrade Costs: 25-50% of original investment every 3-5 years

- IT Staff Requirements: Dedicated team for maintenance and support

Operational Advantages That Drive Results

Accessibility & Remote Operations Cloud solutions enable secure access from any device, anywhere – critical for today’s distributed workforce and multi-location operations.

Scalability Without Limits: Add users, increase capacity, or expand functionality instantly without hardware procurement or installation delays.

Security Beyond Your Capabilities: Enterprise-grade security infrastructure, regular updates, and compliance certifications that exceed most internal IT capabilities.

Automatic Updates & Continuous Innovation Always have access to the latest features, security patches, and performance improvements without manual intervention.

The ROI That Changes Everything: Quantified Benefits of Cloud Manufacturing Software

Financial Performance Metrics

Cost Reduction Achievements:

- 30-50% reduction in IT infrastructure costs

- 20-35% decrease in software maintenance expenses

- 15-25% savings in operational overhead through automation

Revenue Growth Catalysts:

- 10-20% improvement in on-time delivery performance

- 25-40% reduction in inventory carrying costs

- 15-30% increase in overall equipment effectiveness (OEE)

Operational Excellence Statistics

78% of manufacturers report the most significant ROI from digital transformation initiatives. Here’s what leading manufacturers are achieving:

Production Efficiency:

- Real-time visibility into production status across all locations

- Predictive maintenance reduces unplanned downtime by 30-50%

- Automated scheduling improves resource utilization by 20-35%

Quality & Compliance:

- Digital traceability ensures 100% lot tracking and recall capabilities

- Automated quality checks reduce defects by 25-45%

- Compliance reporting cuts audit preparation time by 60-80%

Supply Chain Optimization:

- Demand forecasting improves inventory turnover by 25-40%

- Supplier collaboration reduces procurement lead times by 15-30%

- Multi-location coordination optimizing stock allocation and transfers

Innovation & Growth Enablement

Market Responsiveness:

- Rapid product introduction with integrated PLM capabilities

- Custom manufacturing capabilities without system limitations

- Data-driven decision making with real-time analytics and reporting

Competitive Positioning:

- Industry 4.0 readiness with IoT integration and smart manufacturing capabilities

- Customer satisfaction improvements through better delivery performance and quality

- Talent attraction with modern, user-friendly technology platforms

Ready to Transform Your Manufacturing Operations?

The question isn’t whether to adopt cloud manufacturing software – it’s how quickly you can implement it to gain a competitive advantage.

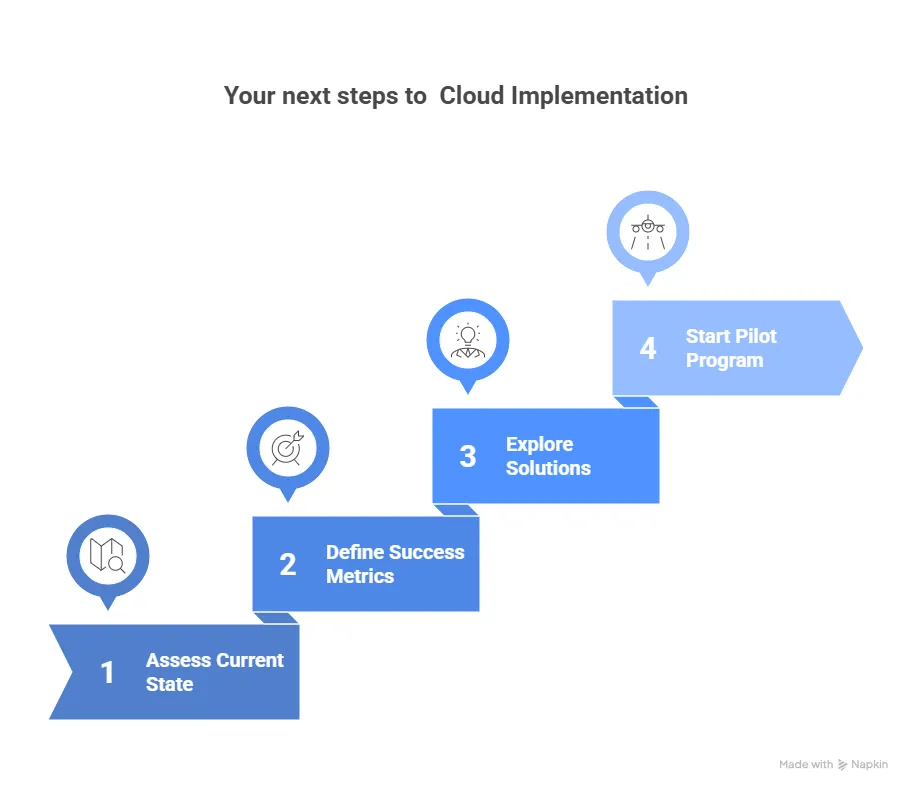

Your next steps:

- Assess Your Current State: Identify inefficiencies, manual processes, and integration challenges in your current operations

- Define Your Success Metrics: Establish clear ROI targets for cost reduction, efficiency improvements, and growth enablement

- Explore Leading Solutions: Request demonstrations from top vendors that align with your industry and operational requirements

- Start with a Pilot Program: Implement cloud solutions in a specific area to demonstrate value before full-scale deployment

Ready to get started? The manufacturers already implementing cloud solutions are establishing competitive advantages that will be difficult to overcome. The time to act is now.

Frequently Asked Questions

Q1. What is cloud manufacturing software, and how does it differ from traditional systems?

Cloud manufacturing software is a comprehensive suite of applications hosted on cloud infrastructure that manages all aspects of manufacturing operations – from production planning and execution to inventory management and quality control. Unlike traditional on-premise systems, cloud solutions offer.

Q2. How quickly can we see ROI from cloud manufacturing software implementation?

Most manufacturers begin seeing measurable benefits within 3-6 months of implementation. Digital transformation initiatives can deliver up to 200% ROI in the first year alone.

Q3. What are the costs involved in developing cloud manufacturing software?

The cost of building cloud manufacturing software varies significantly based on complexity, features, and development approach, typically ranging from $100,000 to $2+ million for a comprehensive solution.

Q4. Can cloud manufacturing software integrate with our existing systems?

Yes, modern cloud manufacturing software offers robust APIs and pre-built connectors to seamlessly integrate with existing ERP, CRM, MES, and legacy systems without disrupting current operations.

Q5. How do we ensure data security and compliance in cloud environments?

Cloud manufacturing platforms implement enterprise-grade security measures, including end-to-end encryption, multi-factor authentication, regular security audits, and compliance with industry standards like ISO 27001, SOC 2, and manufacturing-specific regulations.