Table of Contents

Introduction

Consider your morning coffee. Or that shiny new gadget you just opened. Getting them to you is a big, intangible dance – a supply chain.

But this dance has plenty of spots where things can go wrong.

It’s not merely a late truck delivery.

Picture an entire country experiencing problems, or a major company going out of business (ouch, nearly 9 out of 10 companies have had that sting!).

Even stealthy cyber attacks can bring everything to a shutdown (the experts are really concerned about this!). Ignoring these unseen threats is risky.

So, what’s the intelligent thing to do? It’s not guessing on what might occur.

It’s becoming strong enough to cope with surprises. It’s Supply Chain Risk Management Solutions.

It’s planning ahead and saying, “Uh oh, what if.?”

And then having a plan so your business doesn’t fail.

Because today, your supply chain is not only valuable; it can also be a weakness. Are you prepared to witness the issues lurking in the shadows?

Supply Chain Risk Management Solutions: Overview of Supply Chain Risk Management Solutions

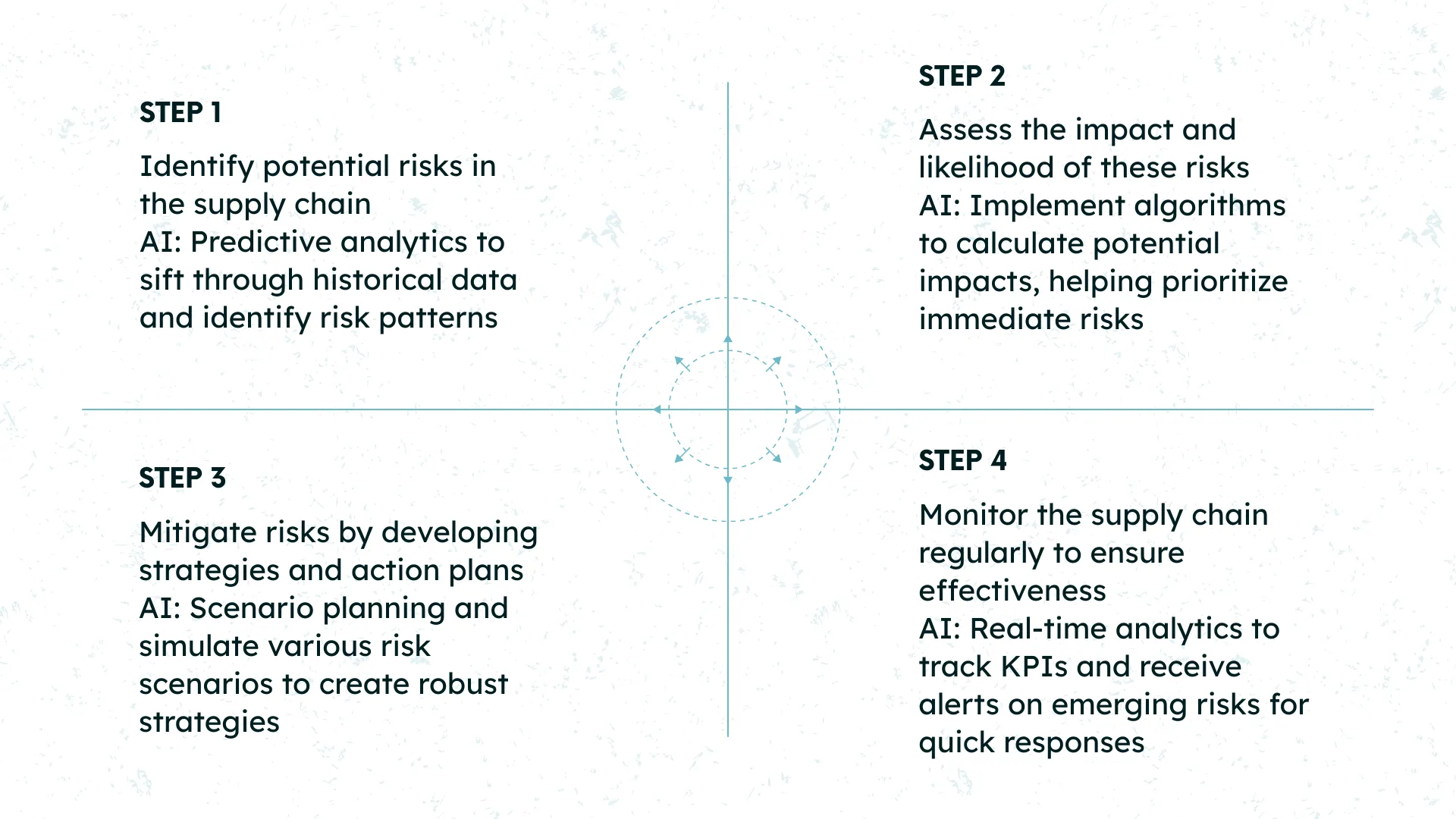

Supply Chain Risk Management (SCRM) is the practice of identifying and reducing potential weaknesses in a firm’s supply chain.

With Gartner reporting that just 21% of organizations possess a highly robust network, the necessity for effective SCRM is more apparent than ever.

By reducing risks, SCRM greatly protects a firm’s operations, reputation, and financial performance.

Adopting strong Supply Chain Risk Management Solutions allows organizations to learn complexity and stay in the game.

Seize the opportunity to bolster your supply chain and protect your future.

Supply Chain Risk Management Solutions: Predictive Analytics Explained

Suppose you’re a captain steering a vessel across a rough sea. You don’t want to encounter rough waves and rocky shores, do you?

Adjusting your sails and sailing according to the winds can be the difference between life and death.

In the turbulent world of supply chains, AI-powered predictive analytics is your guiding instrument, helping you foresee problems and pilot your organization to safety and success.

While supply chains face with unmatched complexity, the outcomes are telling:

Limited Visibility: Fewer than 43% of companies claim to have complete visibility into their tier-one supplier performance (KPMG).

High Costs of Disruption: Disruptions cost large companies an average of $182 million per year (Interos).

Role of Predictive Analytics in Supply Chain Risk Management Solutions

Predictive analytics is the base of contemporary supply chain risk management solutions. Here’s why:

1. Anticipating Disruptions

Predictive analytics aids companies to recognize possible disruptions and changes in demand by customers.

Methods such as data mining, time series forecasting, and regression analysis enable organizations to analyze the whole supply chain from procurement to delivery.

2. Logistics Optimization

Predictive analytics optimizes delivery routes by considering real-time conditions including traffic, weather, and road disruptions.

Combination with IoT devices enables real-time shipment tracking, enabling companies to have better control over logistics.

Real-World Use Case: A trucking firm leveraging predictive analytics routes trucks in anticipation of a snowstorm, which results in deliveries on time.

3. Smarter Inventory Management

Merchants greatly benefit when seasonal sales statistics and market forecasts are predicted.

Preparing ahead of spikes in demand—such as carrying rain umbrellas ahead of a predicted rain—is enabled, avoiding stockouts and forgone sales.

Real-World Use Case: A large retail chain forecasts history sales with weather trends and readjusts stock in anticipation.

Supply Chain Risk Management Solutions: Improved AI Integration for Real-Time Risk Analysis

Source: Gartner Supply Chain Innovations Report, August 2023.

Key Players: IBM, SAP.

Businesses are increasingly using AI-based platforms to analyze and react to supply chain risks in real-time.

These platforms use massive amounts of data to detect possible disruptions, allowing proactive actions that improve operational resilience.

Supply Chain Risk Management Solutions: Controversial Take

As much as there is grand promise in AI-based predictive analytics, some practitioners are warning against blind dependence on algorithms.

This can create a disconnection from local knowledge and experience because managers will start to have blind faith in the technology.

Disregarding the complexity and unpredictability of actual situations can leave organizations vulnerable to more risk if their predictions turn out to be incorrect.

1. Analyzing Historical Data Process

Collecting High-Quality Data: The quality of historical data determines effective risk forecasting. Businesses need to adopt sound data collection methods, such as:

Surveys: Capturing stakeholders’ views.

Transactional Data: Processing purchase history and sales patterns.

IoT Sensors: Collecting real-time data from the supply chain.

A Deloitte study indicates that **data-driven organizations are 5 times more likely to make quicker decisions, underscoring the value of actionable insights.

Data Cleaning and Preparation: Data collected must be properly cleaned and prepared to ensure accuracy.

Actually, 70% of a data scientist’s time is typically devoted to data preparation. This groundwork sets the stage for valuable analytics and efficient risk management.

2. AI Algorithms for Risk Prediction

Predictive analytics utilizes different AI algorithms designed for particular purposes:

Regression Analysis: A method used for forecasting demand by studying relationships between variables in an attempt to estimate future outcomes.

Decision Trees: Visualization tools making decisions straightforward with an easy assessment of possible ramifications.

Neural Networks: As a way to unveil complex patterns from big datasets, these programs are well suited to in-depth risk analyses.

3. Predictive Analytics Applications within Supply Chain Risk Management Solutions

Manufacturing Example: One top manufacturer used AI-based predictive analytics to predict demand fluctuations, realizing a 30% drop in excess inventory.

This not only saved costs but also increased responsiveness to changes in the market.

Retail Example: Walmart

Challenge: The cost of an average disruption in retail is roughly $1.1 million (University of Tennessee).

Solution: Walmart applies predictive analytics to optimize demand forecasting and inventory management.

Through the examination of customer purchasing history and seasonal patterns, Walmart makes accurate product demand predictions.

Outcome: This degree of accuracy enables Walmart to maximize inventory levels, minimize excess stock, and enhance customer satisfaction.

Logistics Example: UPS

Challenge: Effectively driving complex delivery routes.

Solution: UPS applies predictive analytics to plan delivery routes, considering real-time traffic and weather data.

Outcome: This strategy reduces fuel usage and operating expenses with more precise estimates of delivery times.

Logistics Example: DHL

Challenge: High-tech industry disruption costs can be up to $3.5 million (Business Continuity Institute).

Solution: Predictive models in DHL make demand forecasting and route optimization more effective.

Outcome: This pre-emptive approach enhances customer satisfaction and operational cost-effectiveness. Managing such risks comprehensively from route planning to understanding liability frameworks when incidents occur requires both technological tools and awareness of regional legal landscapes, whether working with a Florida trucking accident lawyer or other specialized professionals.

Best Supply Chain Management Software Solutions

With the current competitive business environment, efficient supply chain management software solutions play a significant role in maximizing efficiency and minimizing risks.

The following four are among the best solutions to advance your supply chain operations:

1. SAP Integrated Business Planning (IBP)

SAP IBP combines real-time information to facilitate demand planning as well as inventory optimization.

SAP IBP provides useful tools for scenario planning as well as predictive analytics, which enable companies like Coca-Cola to harmonize supply and demand.

2. Oracle Supply Chain Management Cloud

Oracle SCM Cloud offers end-to-end supply chain visibility, integrating AI in logistics, order management, and procurement.

Unilever gains through this platform by enhancing transparency and responsiveness.

3. Manhattan Associates Supply Chain Solutions

Manhattan Associates specializes in inventory, transportation, and fulfillment optimization, best suited for retailers and manufacturers.

Walmart uses these tools to efficiently handle inventory and minimize wastage of stock.

4. Infor CloudSuite Supply Management

Infor CloudSuite improves collaboration and leverages advanced analytics for supply chain operations.

The Hershey Company depends on it to automate procurement and improve visibility.

4. Obstacles to Deployment of Predictive Analytics

Even though the gains are significant, there are issues:

Data Protection Issues: Withholding compliance from data protection statutes becomes more crucial.

Integration Complexity: Most businesses have difficulty merging new analytics technology with existing applications.

Shortage of Skills: The absence of competent analysts is capable of derailing successful analysis of data to the point of being unable to maximize predictive analytics.

5. Supply Chain Risk Management Solutions: Best Practices for Success

To make the best of predictive analytics, organizations must adopt the following practices in supply chain risk management solutions:

Continuous Data Monitoring: Keep updating and monitoring data to keep it relevant and accurate.

Collaboration Between Teams: Encourage collaboration among IT and supply chain teams to sync goals and maximize analytical efforts.

Training and Development: Invest in developing staff to improve data literacy, enabling them to leverage predictive analytics tools to maximum effect.

6. Supply Chain Risk Management Solutions: Future Trends in Predictive Analytics

Advanced Machine Learning

As AI technologies continue to evolve, anticipate more advanced machine learning algorithms to support improved real-time decision-making abilities.

Integration of Real-Time Data

Solutions in the future will continue to depend on real-time data to offer timely insights to businesses, further enhancing supply chain resilience.

AI-powered predictive analytics is not only revolutionizing; it’s transforming the way organizations design Supply Chain Risk Management Solutions.

Through these insights, businesses are able to leverage uncertainty and create more agile, robust supply chains.

Those who embrace them now will be ready to excel in the intricate and constantly changing world of global supply chains.

The moment is now—accept predictive analytics and set yourself up for success!